Dye sublimation is a process that uses a special heat sensitive dye to print graphics and text onto paper.

The paper is then placed on a sublimatable item and both are placed into a heat press for about 20~45 seconds

at 180-230 degrees.

When the cycle(sublimation) is completed, the image on the paper has transferred to the item and has actually

become a part of the surface.

If you run your finger across the surface of a sublimated plate you will feel nothing.

The reason for this is that sublimation is always done on a polyester, polymer or polymer coated item.

At high temperatures, the solid dye converts into a gas without ever becoming a liquid.

The same high temperature opens the pores of the polymer and allows the gas to enter.

When the temperature drops, the pores close and the gas reverts to a solid state.

It has now become a part of the polymer.

For this reason, true dye sublimation cannot be done on natural materials like 100% cotton.

Natural fibers and non-coated materials have no "pores" to open.

Inkjet printers use a liquid filled inkjet cartridge that has a suspension of the dye in it and requires transfers to be printed on special coated inkjet paper.

The printer should be dedicated to sublimation as the cartridges cannot be easily or cheaply switched with

regular cartridges for regular document printing.

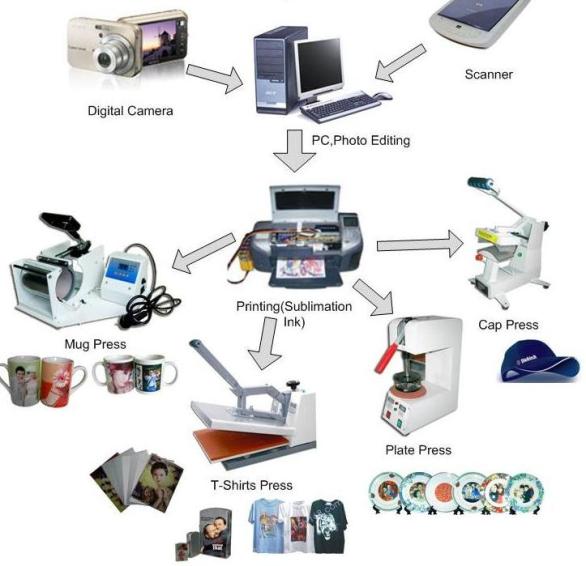

Sublimation Process

1. Design Your Transfer

A computer, graphic design software, printer with sublimation inks, and a heat press are all you need to begin

making full color items.

With a scanner, digital camera or any electronic image or clip art you have a flexibility to create colorful

designs and add photographs.

Once you've created an electronic design, you can create as many or as few transfers as you needs.

2. Print Your Transfer

With your sublimation printer and cartridges, you're ready to start printing transfers.

Sublimation produces vibrant color that surpasses silk screening or hot stamping-perfectfor logos, photos, clip art or other images.

3. Heat Your Transfer

Sublimation inks are specially formulated to convert directly from a solid to a gas under heat and pressure.

While in a gaseous state, the inks are attracted to certain types of synthetic surface.

The inks actually penetrate and bond with the Unisub surface so that apermanent, durable image is created.

Other heat transfer methods only apply color to the surface of the substrate, resulting in a product that can be

easily scratched or damaged.

4. Press Time & Temperature

| Material |

Time |

Temperature |

Reference |

| Coated Metal |

1min |

195 ℃ |

Heat from the back of Aluminium |

| ANODISE Aluminium 1mm |

1min 30sec |

160 ℃ |

Heat from the back of Aluminium |

| ANODISE Aluminium 0.5mm |

1min |

160 ℃ |

Heat from the back of Aluminium |

| Mouse Mat |

1min 25sec |

205 ℃ |

Heat face up |

| Clear Polyester(*) |

40-45sec |

200 ℃ |

Heat face up |

| Lycra/Spandex(*) |

40-45sec |

200 ℃ |

Heat face up |

| Canvas(**) |

1min |

210 ℃ |

Heat face up |

| Matt Polycarbonate |

1min-1min30sec |

177 ℃ |

Sandwich between 2 sheets of paper |

| Tiles(in Tile Presser) |

4-5min |

205 ℃ |

Heat face down |

| Mug(in Mug Presser) |

4-5min |

205 ℃ |

Tape image onto mug firmly |

| Foam Board(EVA) |

1min |

165 ℃ |

Heat face up ? cool under flat place |

| 1mm White Plastic (HIPS) |

2min |

160 ℃ |

Heat face up |